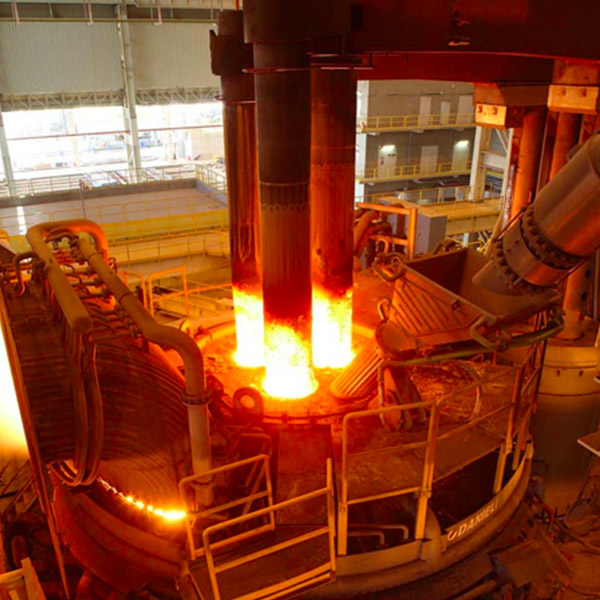

Our primary focus lies in the production of Tempcore SG Rebars, which form the core of our operations. Utilizing advanced technology in our integrated steel plant, we adhere to international standards to create high-quality billets. These billets serve as the foundation for the production of Thermo Mechanically Treated (TMT) Bars. The use of self-manufactured raw materials not only contributes to cost-effective production but also offers advantages to the end user.

The resulting TMT Bars exhibit exceptional malleability, ductility, and High Corrosion Resistance (HCR), ensuring consistent quality grades and customer satisfaction. Tempcore SG Rebars have established a significant presence across various regions in the country, and their popularity continues to grow rapidly. This success can be attributed to the widespread acceptance of our products and a leading position in repeat purchases. Despite challenges in the steel industry, Tempcore SG Rebars consistently prioritize quality and reliable delivery.

Our steel meets the highest standards, so your project stands strong, guaranteed.

We're invested in your success, working alongside you to turn dreams into reality.

3. We believe in building a greener future, with eco-friendly practices and resource efficiency.