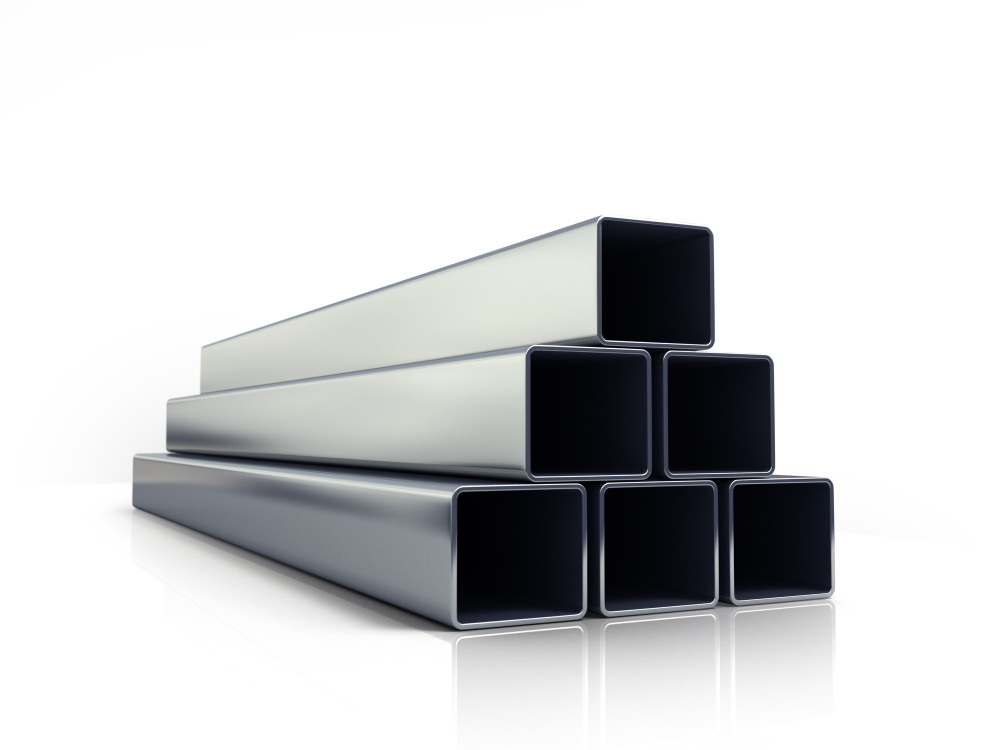

We produce Hollow Sections tailored to meet customer specifications, featuring anti-rust oil coating both inside and outside the tubes for secure delivery to end customers. In the manufacturing process, flat steel plates undergo a transformation, gradually assuming a round shape with edges prepared for welding. The edges are then welded together to create the initial tube, which subsequently passes through a series of shaping stands. These stands mold the round HSS (mother tube) into its final square or rectangular form. The resulting sections are equipped with anti-rust oil coating, ensuring safe delivery to end customers.

Our Hollow Sections are available in a variety of dimensions, sizes, and specifications, making them versatile for applications in furniture industries, bus body construction, structural projects, and fencing. Their exceptional durability makes them well-suited for these purposes. The entire range is offered at reasonable prices and is delivered within the stipulated time frame.

Square and rectangular Hollow Section Pipes & Tubes have extensive applications due to their capacity for weight control and high stress resistance. Our structural tubes find utility in lifting and load-handling systems, serving as crucial components in lift arms (such as batten and tower mast) for mobile cranes, marine cranes, sea port cranes, rocket and spaceship launch towers, and other superstructural areas. Additionally, our hollow sections are widely utilized in furniture industries, domestic applications, and the fencing industry.

The versatility of these hollow sections allows for various sizes beyond those mentioned above, catering to specific requirements upon request.

Our steel meets the highest standards, so your project stands strong, guaranteed.

We're invested in your success, working alongside you to turn dreams into reality.

3. We believe in building a greener future, with eco-friendly practices and resource efficiency.