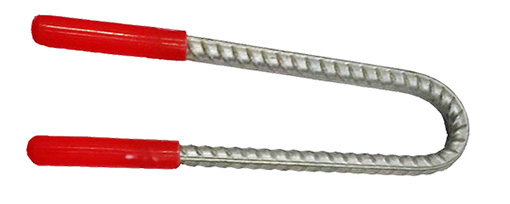

Introducing Zinc Coat TMT Bars, featuring specialized Zinc Coating and proudly manufactured for the first time using CGR Technology – Continuous Galvanizing Rebars. These Zinc-coated TMT Bars offer superior quality, an extended lifespan, and an enhanced product aesthetic, coupled with distinctive packaging.

Zinc Coat TMT bars undergo a meticulous process of Zinc coating followed by surface passivation treatment. This results in the creation of a protective double-layered final product, ensuring prolonged life within a concrete environment.

The Zinc coating provides unparalleled protection, surpassing other coating options. The coating process is executed using the patented Continuous Galvanizing Rebars (CGR) method, guaranteeing optimal coating thickness. This meticulous process ensures a finer final product that is highly resistant to corrosion, with consistent and uniform coating thickness and zero coating gaps in the final output.

Since the salt spray test is a standardized, widely practiced, and accepted corrosion test method according to ASTM B117-11, utilized to assess the corrosion resistance of surface coatings. Comparative salt spray testing (continuous exposure to 5% NaCI) of Zinc Coat TMT bars and ordinary rebars revealed that there was absolutely no rust on Zinc Coat TMT bars, even after 100 hours of exposure to the solution. In contrast, the uncoated ordinary rebars developed a complete superficial red oxide layer after a brief exposure period of 20 hours.

Our steel meets the highest standards, so your project stands strong, guaranteed.

We're invested in your success, working alongside you to turn dreams into reality.

3. We believe in building a greener future, with eco-friendly practices and resource efficiency.